EcoMister Models

HD30

HEAVY DUTY SOLUTIONS FOR HIGHLY CONTAMINATED WATER

All units in the HD series are designed to operate in the harshest environments 24 hours a day, 365 days a year, and are available in land based, trailer based and float based configurations depending on your specific needs. Pump packages are also available to match the needs of your site along with wind speed and automated control systems.

HD30 Performance Highlights

0

HP of Motor

0

Inch Turbine Size

0

GPM Capacity

0 M

US Gallons Annual Disposal Volume at 50% Efficiency

0

FT Max Throw from Machine

features & specifications

Longevity in the Harshest Environments

The HD30 EcoMister is built with our stainless steel axial flow turbine and our stainless steel directional wind tunnel and both are coated with specially blended powder coating for durability against the elements and to meet the corrosive conditions of operating sites. Motors are built to exceed IEEE-841 Severe Duty standards and are 3rd party tested to guarantee a 0.5 mil vibration rate to maximize the motor’s operational lifetime.

Low Operating Costs

To maximize efficiency and minimize operational costs the Turbo-mist turbine is spun to a specific size allowing for manufacturing tolerances of fewer than 30 thousandths of an inch. This allows the turbine to operate at lower horsepower requirements but provides air volumes comparable to a much larger and more costly unit. Systems are designed for minimal maintenance and down time through thoughtful design like simplified greased ports on the motors to a quick release camlock on the nozzle ring manifold.

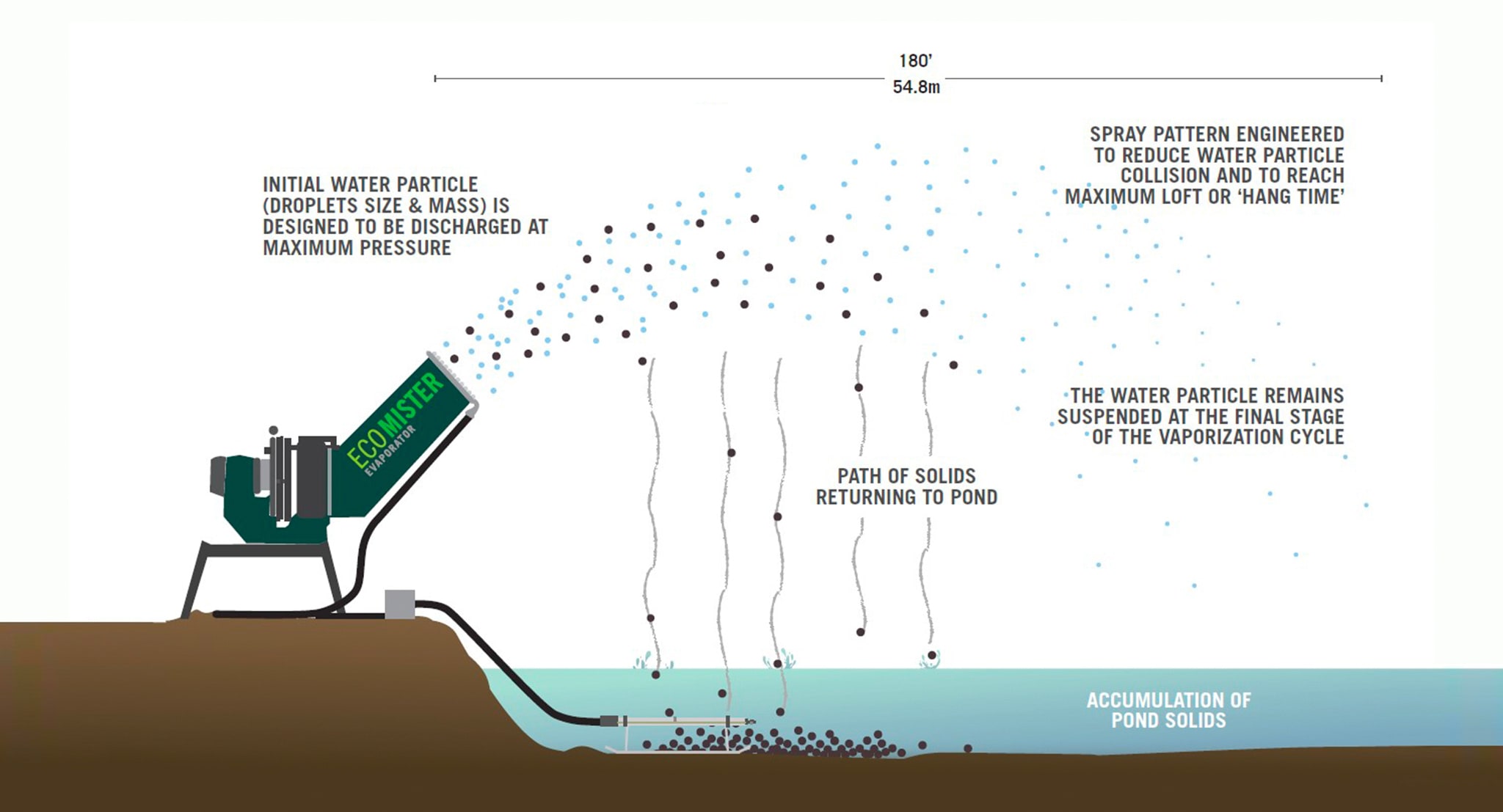

Best in class evaporation

Equipped with a dynamically balanced aluminum fan and our directional air delivery tube which creates true laminar air flow, the spray pattern is engineered to reduce water particle collision and to reach maximum loft or “hang time”. This longer “hang time” along with a specifically engineered droplet size maximizes your evaporation efficiency.

Flexibility

Each evaporator is available in multiple base configurations including fixed land based, trailer based, and float based, providing the best solutions and setup for the needs of each site. A 360 degree rotating base with multiple locking positions along with a simplified pitch adjustment system allows the operator to easily adjust the direction and angle of the wind tunnel to optimize plume control and evaporation efficiency in varying site conditions.

Powerhead

- 30” dual bearing stainless steel axial flow Turbo-mist turbine

- Specially blended powder coated aluminum fan (stainless steel upgrade available for severe duty)

- Stainless steel fan shaft

- Powder coated stainless steel multi positional wind tunnel with easy adjustment bracket

- Stainless steel motor shaft

Motor Mount and Base

- Available in land based, trailer based and float based configurations for maximum flexibility

- Base has easy to operate 360-degree rotation ability with safety pin

- Motor mount is designed for easy alignment and adjustment should removal for maintenance be necessary

Water Delivery System

- Quick release stainless steel nozzle ring equipped with 30 Teflon Spiral Jet nozzles (additional nozzle material options available)

- 80.1 GPM (303 LPM) at 150 PSI (10 BAR)

- 3rd party pressure tested hoses

- Standard and customizable pump packages available in Single, Dual or Tri Pack configurations

- Standard pump packages come with high efficiency multi-stage centrifugal pump with electric motor, a control panel with low pressure auto shutdown, check valves to prevent loss of prime and to protect the pump, a self-cleaning filter and an electric primer

Electrical

- 40 HP (operational HP of 23.5) IEEE-841 Severe Duty High efficiency 3-phase motor

- Global voltage and frequency motor configurations available for any location

- Control panels manufactured in watertight NEMA 4 enclosures with exterior alarm lights

Warranty

- All units have a minimum one-year parts and labour warranty

How It Works

Harnessing the natural process of evaporation is the future of wastewater disposal. Electric or Fuel powered motor, the EcoMister Evaporator series from Slimline Manufacturing uses our Turbine technology to loft wastewater high into the air, creating sustained ‘hang time’, and allowing nature to evaporate the water, while the solids are returned to the pond.

Operational Costs and Savings

The EcoMister Evaporator offers a significant cost advantage for your wastewater disposal. By enhancing the natural evaporation process, the EcoMister Evaporator allows you to evaporate wastewater in multiple industries such as Mining, Municipal Wastewater, Landfill Leachate, Oil & Gas, Food Processing and Power Generation.

ON AVERAGE, OUR CUSTOMERS SPEND $0.0010 PER US GALLON ON DISPOSAL. A SIGNIFICANT SAVINGS OVER ALTERNATIVE DISPOSAL METHODS.

OEM Parts & Customer Support

Global coverage and the highest standards of performance excellence. We offer factory-backed OEM EcoMister™ Genuine Parts to support your needs and your customers. We stand behind our product, and offer our expertise and knowledge to help you get the right parts in a timely manner. 2-Day Delivery Guarantee*

*Delivery guarantee is 2 standard business days for delivery services within North America, provided by UPS. The cost of shipping will depend on your location, the carrier chosen, and the size and weight of the product purchased.